Vinyltrichlorosilane FR-151

Product Details

Description:

Triethoxyvinylsilane FR-151 is a Light yellow to colorless liquid

CAS NO.:

78-08-0

Molecular formula:

C₈H₁₈O₃Si

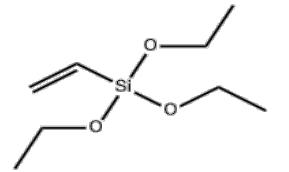

Chemical Structure:

Specification:

| Items | Unit | Specification |

|---|---|---|

| Appearance | ---- | Light yellow to colorless liquid |

| Density | g/ml, 20℃ | 0.9105-0.9115 |

| Refractive index | 25℃ | 1.3960±0.0010 |

| Boiling point | ℃ | 160.5 ℃ |

Application:

● Used for polyethylene cross-linking producing wire cable insulation and sheath materials.

●The heat-resistant pipes, hoses and films made of polyethylene cross-linking

● It is suitable for dipping glass fiber and inorganic silicon-containing filler. Improve and enhance the infiltration, bonding properties of resin and glass fiber, thereby effectively improving the mechanical strength and electrical performance of glass and plastic laminates, Especially the wet mechanical strength and electrical performance. It also significantly improves the weather resistance, water resistance, heat resistance , and prolongs the service life of the product. In addition, it also endows the product with better electromagnetic wave transmission.

● FR171 is copolymerized with a variety of monomers and can be made into special coatings.

● Used as a filler for processing special rubber. Treating the filler of special rubber with this product can improve dispersion performance, thereby increasing the blending ratio of the filler with rubber and increasing the tear strength of the rubber. And it can improve the bonding performance of rubber, metal and fabric

● Sealant for producing plastic packaging materials for electronic components. In 1, 2 polybutadiene plastic packaging materials, FR-151 is used to treat the filler quartz powder to improve the three-way combination of polybutadiene resin and quartz powder, enhance the compactness of the plastic, and improve the moisture resistance of the plastic packaging material.

● Used to moisture-proof treatment for the surface of electronic components. It can be used in the surface moisture-proof treatment of the disc-type fine-tuning ceramic dielectric capacitor anti-high voltage composite dielectric capacitor to improve the moisture-proof performance surface smoothness of the product, and increase the product qualification rate.

● Used for surface treatment of composite glass intermediate layer. producing aircraft windshields or other products, add this product to impregnate poly butyl methacrylate film, and adhere to the glass to improve adhesion without cracking.

Packing:

210L Iron Drum/ 1000L IBC Drum

Storage and transportation:

Store in a cool and ventilated place, away from fire, heat sources, and do not store separately from oxidants, alkalis, etc.

Note:

As your specific application and use conditions are out of our knowledge, please kindly check the applicability and application range before use of this product. Above information is just for your information.

Categories

Hot-Sale Product

Consultation hotline

You can contact us in the following ways and look forward to your call for consultation

+86 13285355246

rhea@sdyingrui.cn