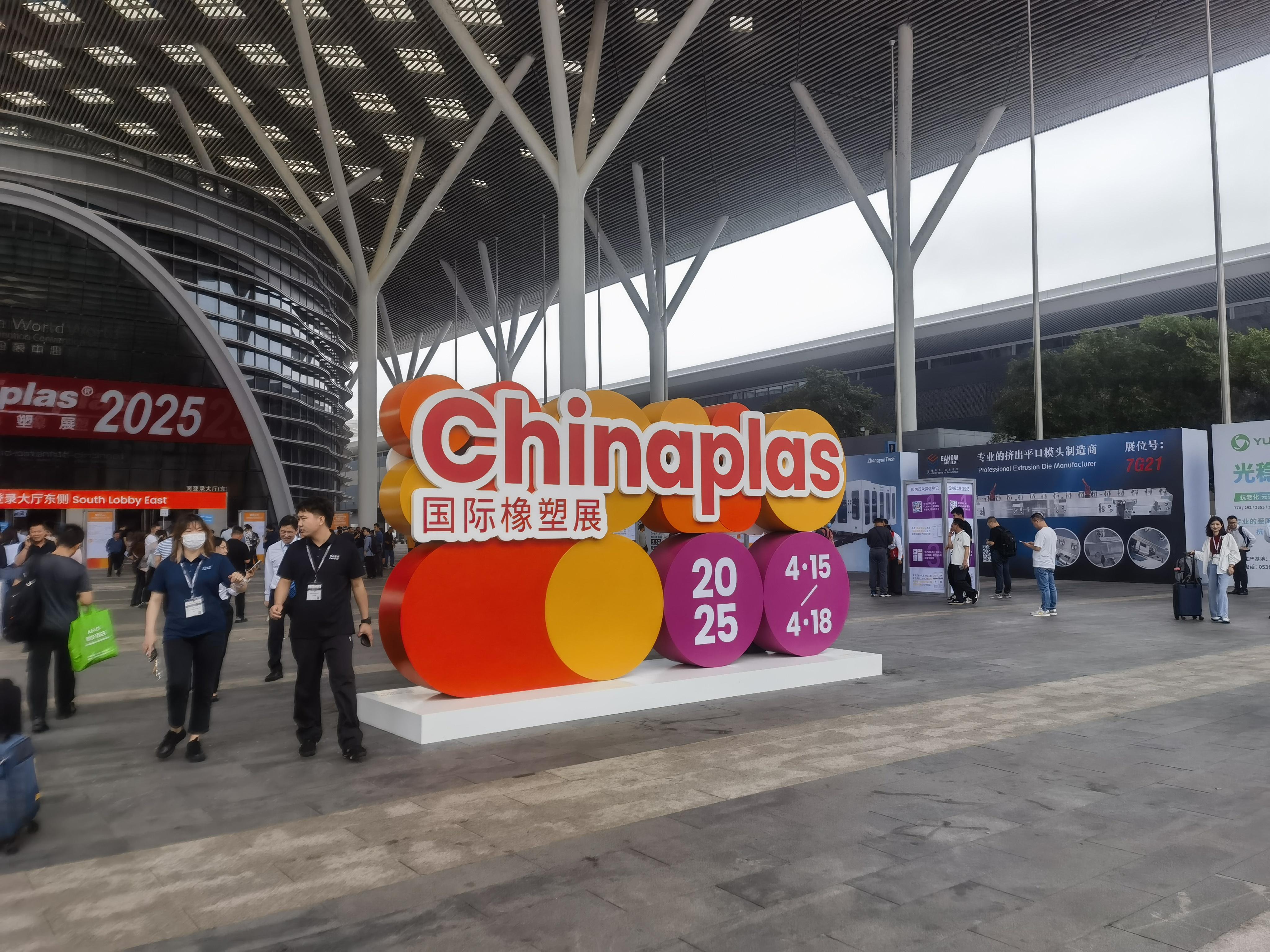

Anti-blocking agents at CHINAPLAS 2025

Anti-blocking agents at CHINAPLAS 2025

Date: 2025-04-27 14:45

Category: News

Author: Admin

At CHINAPLAS 2025 in Shenzhen, numerous international and domestic suppliers showcased anti-blocking agents, primarily silica and wax-based, crucial for preventing film adhesion during processing and ensuring smooth handling. Key players like Evonik, BYK, and various Chinese manufacturers presented solutions for diverse film applications.

Reflecting on CHINAPLAS 2025, held in Shenzhen from April 15th to 18th, the Anti-blocking Agents section was crucial for addressing processing challenges in film and sheet production within the plastics industry. These additives prevent adhesion between adjacent layers of film, ensuring smooth unwinding and handling. A variety of international and domestic companies showcased their solutions, focusing on efficiency, compatibility, and specialized applications.

Likely Exhibitors and Their Offerings:

Evonik Industries (Germany/Global): With their ACEMATT® range of silica-based matting agents, some grades also function as excellent anti-blocking agents in films. They likely highlighted options for various film types and processing conditions.

BYK-Chemie GmbH (Germany): BYK offers a range of surface additives, including silica and wax-based products, that can act as anti-blocking agents in polyolefin and other films. Their focus might have been on achieving optimal slip and preventing blocking without affecting clarity.

W.R. Grace & Co. (now part of Standard Industries) (USA/Global): Known for their SYLOID® and SYLOBLOC® silica products, Grace likely presented grades specifically designed for anti-blocking in films, offering a balance of efficiency and optical properties.

Clariant (Switzerland/Global): Clariant provides various additives for the plastics industry, including inorganic and organic anti-blocking agents, potentially including their Cesa® range.

Addivant (USA/Global, now part of SK Capital Partners): Addivant offers a range of performance additives for polymers, and they likely showcased their anti-blocking solutions for polyolefins and PVC films.

Fine Organics (India/Global): Fine Organics is a significant producer of specialty additives, and they likely presented their range of anti-blocking agents, including amide waxes and other organic options.

Domestic Chinese Companies: Several Chinese manufacturers specializing in synthetic silica (precipitated and fumed), talc, calcium carbonate, and wax powders would have exhibited their products as cost-effective anti-blocking solutions for various film applications. Look for companies with "抗粘连剂" (anti-sticking agent) or specific mineral/wax names in their product listings. Specific company names can vary, but many focus on industrial minerals and specialty chemicals.

Trading Companies: Numerous trading companies representing both international and domestic anti-blocking agent manufacturers would have also been present.

Focus Areas at the Exhibition:

The exhibits likely highlighted:

Efficiency: Anti-blocking agents that provide effective separation at low loading levels.

Optical Properties: Grades that minimize haze and maintain film clarity.

Slip Properties: Additives that offer controlled slip for smooth processing.

Compatibility: Anti-blocking agents suitable for various polymer types (PE, PP, BOPP, etc.).

Particle Size Distribution: Optimized particle size for effective spacing and minimal die buildup.

In summary, CHINAPLAS 2025 likely featured a comprehensive range of anti-blocking agents from both global leaders and domestic suppliers, addressing the critical need for efficient and high-quality film processing in the plastics industry.

fumed silica

white carbon black

pyrogenic silica

silicon dioxide

hydrophobic fumed silica

hydrophilic fumed silica

Synthetic Amorphous Silica

nanoscale fumed silica

high surface area fumed silica

silica nanoparticles

Shandong Yingrui New Materials Co., Ltd

Email: rhea@sdyingrui.cn; michael@sdyingrui.cn

Tel: +86 13285355246; +86 15154536501

Whatsapp: +8613583505605; +8615154536501

---------------------------------------------------------------------------------------------------------------------

回顾 2025 年 4 月 15 日至 18 日在深圳举行的 CHINAPLAS 中国国际橡塑展,抗粘连剂展区对于解决塑料薄膜和片材生产中的加工难题至关重要。这些助剂可防止薄膜相邻层之间的粘连,确保顺利的退卷和处理。众多国际和国内公司展示了他们的解决方案,重点在于效率、相容性和专业应用。

主要参展商及其产品回顾:

赢创工业(德国/全球): 其 ACEMATT® 系列二氧化硅消光剂中,部分型号也可用作薄膜中优异的抗粘连剂。他们可能重点展示了适用于各种薄膜类型和加工条件的解决方案。

毕克化学(德国): 毕克提供一系列表面助剂,包括二氧化硅和蜡基产品,可在聚烯烃和其他薄膜中用作抗粘连剂。他们的重点可能在于在不影响透明度的前提下实现最佳的爽滑性和防止粘连。

格雷斯(现隶属于 Standard Industries)(美国/全球): 以其 SYLOID® 和 SYLOBLOC® 二氧化硅产品而闻名,格雷斯很可能展示了专门为薄膜抗粘连设计的型号,在效率和光学性能之间取得了平衡。

科莱恩(瑞士/全球): 科莱恩为塑料行业提供各种助剂,包括无机和有机抗粘连剂,可能包括其 Cesa® 系列。

埃迪vant(美国/全球,现隶属于 SK Capital Partners): 埃迪vant 提供一系列聚合物性能助剂,他们很可能展示了其用于聚烯烃和 PVC 薄膜的抗粘连解决方案。

精细有机物(印度/全球): 精细有机物是重要的特种助剂生产商,他们很可能展示了其抗粘连剂系列,包括酰胺蜡和其他有机选项。

中国国内企业: 许多中国国内企业,专注于合成二氧化硅(沉淀法和气相法)、滑石粉、碳酸钙和蜡粉的生产,将展示其作为各种薄膜应用的经济高效的抗粘连解决方案。寻找产品列表中带有“抗粘连剂”或特定矿物/蜡名称的公司。具体公司名称可能有所不同,但许多公司专注于工业矿物和特种化学品。

贸易公司: 众多代表国际和国内抗粘连剂制造商的贸易公司也参加了展会。

展会上的重点领域回顾:

展品很可能突出了:

效率: 在低添加量下即可提供有效分离的抗粘连剂。

光学性能: 能够最大限度减少雾度并保持薄膜透明度的型号。

爽滑性: 提供可控爽滑性以实现平稳加工的助剂。

相容性: 适用于各种聚合物类型(PE、PP、BOPP 等)的抗粘连剂。

粒径分布: 优化的粒径以实现有效的间隔并最大限度地减少模头积聚。

总而言之,CHINAPLAS 2025 很可能汇集了来自全球领导者和国内供应商的全面抗粘连剂产品,以满足塑料行业对高效和高质量薄膜加工的关键需求。